The design and planning for modern manufacturing spaces is generally a process controlled by experts. Their job is to design a space that accommodates machinery and workers in an efficient manner. It may seem relatively easy, yet it can be a complex process. The planners will need to plan for the machines to get the materials they need efficiently, and worker safety is another issue for them to consider. All of these may seem like the most important aspects, yet the look of the area should also be pleasing. Workers tend to be more efficient and do better work in an environment that does not jar their sensibilities.

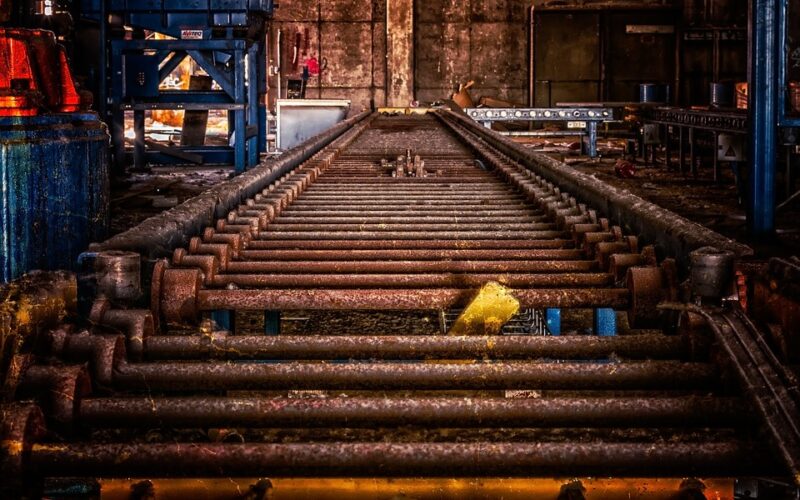

Placing the machinery

Efficient manufacturing processes cut down on the cost of making goods. It is one reason planning is a very important step in creating a work area. Designers need to ensure materials can be fed into machines by workers without slowing down the entire process. Placing the machinery in the right area, clearing needed space around it, and considering the needs of those tending the machines are all part of modern manufacturing palling operations. The end result should be a workable solution that keeps man and machine running at a cost-effective rate.

The need to move materials

There are often many different raw materials that go into the manufacturing of a single item. Each one of them will be delivered to the plant, and they are often stored. Storage spaces will need to accommodate them for size, and some may also be environmentally controlled. Workers should be able to easily access the materials they require at any time, and the need to move materials should not be hampered by a long or twisted route. Clear paths and easy access can be combined to create a more efficient working environment.

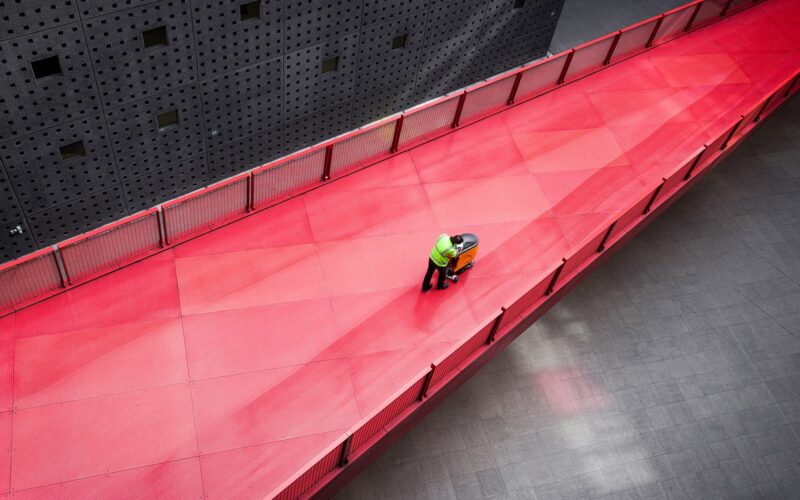

The needs of workers

Many shifts in modern plants last through a regular working day, and the workers will need several different accommodations. They might need a place to eat lunch or dinner, and break rooms are often provided. One more item that might help is the look of the areas where they work and relax. Planners may choose paint colours that guide workers through different areas, or they could choose them to be psychologically comforting. It is important for the paint to last for many years while standing out from the background, so adding hydrous clay or calcined kaolin from Minerals Marketing might be a choice they plan into the budget. These items help with the viscosity and life of the paint. One other additive to paint that could be helpful is recycled glass media. It is part of what makes the life of the paint longer.

There are plenty of small details that can go into creating the most efficient manufacturing plant, and they are all part of the consideration when building. It may seem some details are not important, yet they may be what man and machine need to produce efficiently. Looking at the many options available may be the job of professional designers, but it is the workers in the plant that will enjoy them throughout the years.